Hazard or risk assessments are a critical part of a functional operationalized health and safety program. The potential hazards are identified and categorized based on estimating three factors.

A hazard analysis is used as the first step in a process used to assess risk.

Functional hazard risk assessment. Functional Hazard Analysis FHA The FHA looks at what major failures of function can occur the effects of those failures the risk associated with them and the safety criteria we must meet to make that risk acceptable. Failure Mode and Effects Analysis FMEA The FMEA looks at what happens when each component of the system fails in various ways. The following are the two phases of a functional risk assessment to determine risk priority.

The severity of a fault is any impact on patient safety product quality or data integrity. Probability is the likelihood of the fault occurring at all. The relationship between the severity and probability is the risk class.

The basic purpose of functional safety is to provide defined levels of risk reduction in managing specific hazards associated with some sort of equipment. The levels of risk reduction are determined within a companys overall risk management framework to ensure that the overall risk to people and the environment is as low as reasonably practicable. Functional safety relies on the correct functioning of.

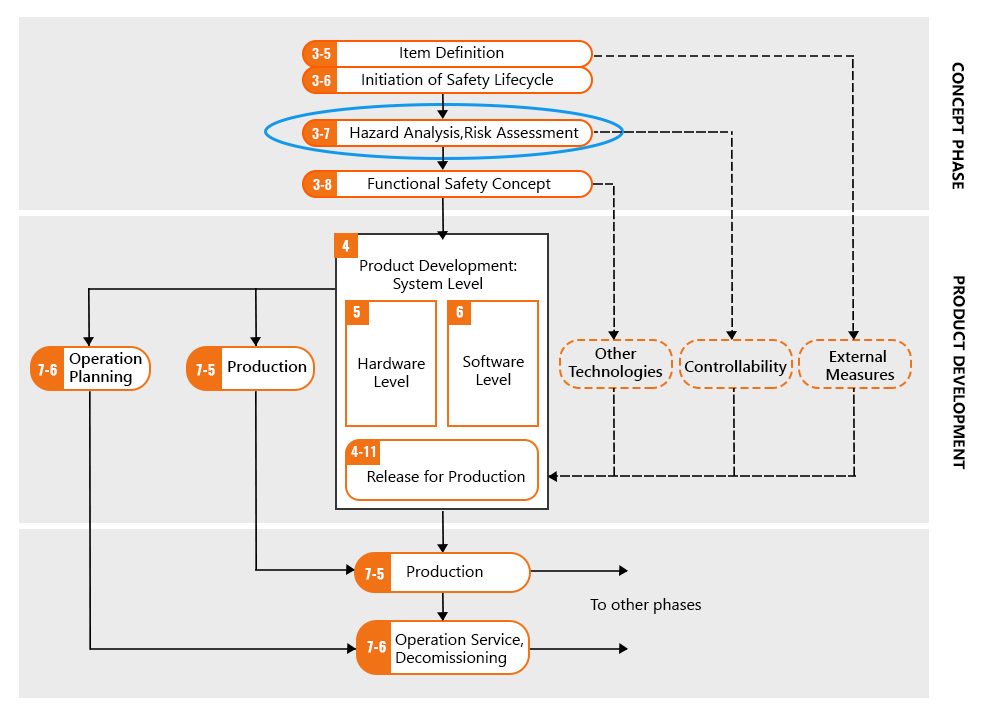

HARA stands for Hazard Analysis and Risk Assessment. In the previous medium articles mentioned below we already saw basic ideas behind identifying hazards and assessing risks. This paper explains the hazard and risk assessment processes that needs to be followed within a Functional Safety Assessment FSA with reference to systems typical of the process industry.

This also paper attempts to highlight some of the pitfalls of carrying out a FSA and how the application of IEC 61508 can be integrated into projects to achieve maximum benefit. Functional Safety Assessment A Stage 5 Functional Safety Assessment FSA was required for a safety instrumented system SIS undergoing upgrade on a Top Tier COMAH chemical plant. We provided the lead assessor to scope plan and deliver an independent assessment report.

The hazard of an inhibitor is estimated from the ratio of Predicted Environmental Concentration PEC to No Effect Concentration NEC. If this ratio is less than or equal to one the ecosystem is safe in the presence of the inhibitor. The NEC values are obtained from PARCOM toxicity data.

In this paper we present and discuss the ISODIS 26262 approach to hazard and risk assessment. The potential hazards are identified and categorized based on estimating three factors. Safety risk assessment features 8 steps.

System operation description 2. Hazards identification processes 3. Evaluation of risk 6.

Mitigation of risk 7. Approval of residual risk 8. The example used in this blog is based on am MCI-based motor control function simply to illustrate hazard analysis and risk assessment flow.

It is the system developers responsibility to perform their own hazard analysis and risk assessment at the system level as prescribed by the applicable functional safety standard for their own designs. The Functional Hazard Assessment FHA is a safety assessment technique defined in SAE ARP4761. It is very different from Fault Hazard Analysis also known by the same abbreviation.

What about Functional Hazard Analysis MIL-STD-882E. Aircraft Functional Hazard Assessment AFHA 14 November 2018 12 Typical aircraft functions may include. Provide structural integrity Provide stability and control in air Provide control of energy in air Provide operational awareness in air Provide a controlled environment in air Provide power generation and distribution.

Building Risk Assessment BRA is a tool used to assess the risks to people in occupied buildings in the facility. This is also sometimes identified as an Occupied Building Risk Assessment OBRA. Stages of a BRA.

FSES apply the three stages of the BRA as required. Partial functional hazard analysis worksheet for preceding example safety requirements derived from ARP 4754 SAE 1994 ID Phase Environ Fn Failure mode rate of development End e ect S DAL fhr Annunc Detect. Recovery Veri ed by 1 City stopgo MC Uncommanded resume Tail end collision II C 1E-8 Low speed lockout PSSA 110 2 Parking low speed MC Uncommanded.

A hazard analysis is used as the first step in a process used to assess risk. The result of a hazard analysis is the identification of different type of hazards. A hazard is a potential condition and exists or not.

It may in single existence or in combination with other hazards and conditions become an actual Functional Failure or Accident. The way this exactly happens in one particular sequence is called a. Hazard or risk assessments are a critical part of a functional operationalized health and safety program.

Not only do they present an opportunity to quantify the amount of risk your organization faces and the percentage of risk you are able to mitigate by putting controls in place but they also help to improve worker participation in safety. In some cases analysts may interchange terminology and refer to a hazard as a risk or vice versa. Caution must be exercised in the use of these terms.

When conducting risk assessment the analyst must consider all possible combinations of hazards that may constitute one particular risk which is the severity and likelihood of a potential accident.