Nates electric motor quality as required by most electric motor customers. What Rice Does to Human Body.

13 HP Inverter motor has a noisy 6203 rear bearing.

Electric motor bearing noise. 3 Zeilen Though the system keeps the motor running the occasional spark occurs between brushes and. Nates electric motor quality as required by most electric motor customers. Several characteristics are included within this EM speciication such as.

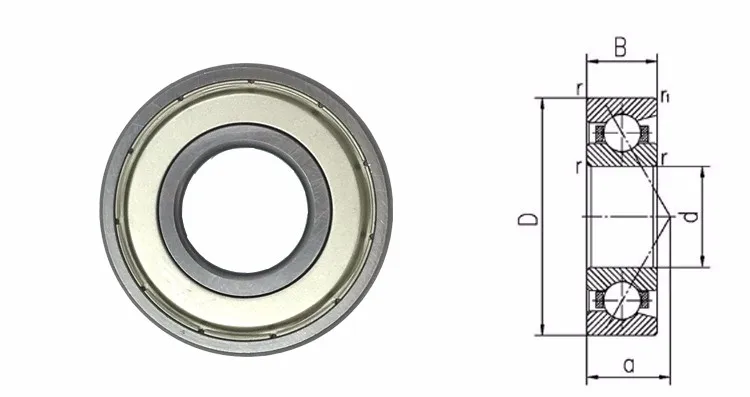

C3 radial internal clearance QE6 noise speciication Capped bearings are illed with a high-quality polyurea-thickened grease Mobil Polyrex EM designated by the SKF sufix GJN. 13 HP Inverter motor has a noisy 6203 rear bearing. The front output end is a 6205 series bearing.

Motor is a Baldor IDNM3534 3 phase 230460 volt inverter. Identifying Bearing Damage Symptoms An electric motor experiencing bearing current displays a range of symptoms. The most obvious symptom is audible noise emanating from the motor bearing it is also one of the last symptoms to present itself usually indicative of advanced bearing failure.

To prevent this use precision instruments such as the SKF shaft alignment tool and Microlog vibration analzer to check alignment and vibration and the appropriate tools and methods when mounting bearings. Bearings always need to have a minimum load to function well. The damage will appear as smearing on the rolling elements and raceways.

In order to prevent this make sure to apply a sufficiently large external load to the bearings. Assess the condition of the motors sleeve bearings. This bearing has a well-defined colored raceway.

The inner race is still intact but the effect of high heat can clearly be seen. These elevated temperature are typically caused by the bearing running with boundary After being in service for a short time elevated noise levels were detected. Excessive noise and increases in vibration and temperature.

Troubleshooting instruments like hand-held vibration pens digital thermometers and electronic stethoscopes help spot bearings in poor operating condition. Find the cause of bearing failuresBearings are built to last so. Some detective work will need to be performed.

Among the various causes of a noisy bearing include manufacturing defects lubrication contamination mounting conditions and application. Manufacturing defects make up only a small portion of faults within bearings as many manufacturers have provisions in place to eliminate these defects. Out-of-round housings dirty surfaces and rotating shields or seals are often the result of poor installation or mounting.

Slight motor vibration is normal. The presence of a variable frequency drive VFD while helpful for decreasing energy use introduces electrical noise in the form of Common Mode Current. Common Mode Current can increase vibrations to dangerous levels that can cause audible noise issues and more worryingly badly damage your motor bearings.

Motor has 2 speeds hooked up and is very noisy on high speed. The bearing is bad and I had to replace it. An electric motor generally runs maintenance-free for many years.

It has only one moving part the armature which has one or more wire windings wound around the central section. The end spindles on the armature are seated between bearings which enable the motor to rotate smoothly and quietly. However electric motor bearings do wear or get exceptionally dry over time.

Pool Motor Replacing The Bearings - YouTube. What Rice Does to Human Body. If playback doesnt begin shortly try restarting your device.

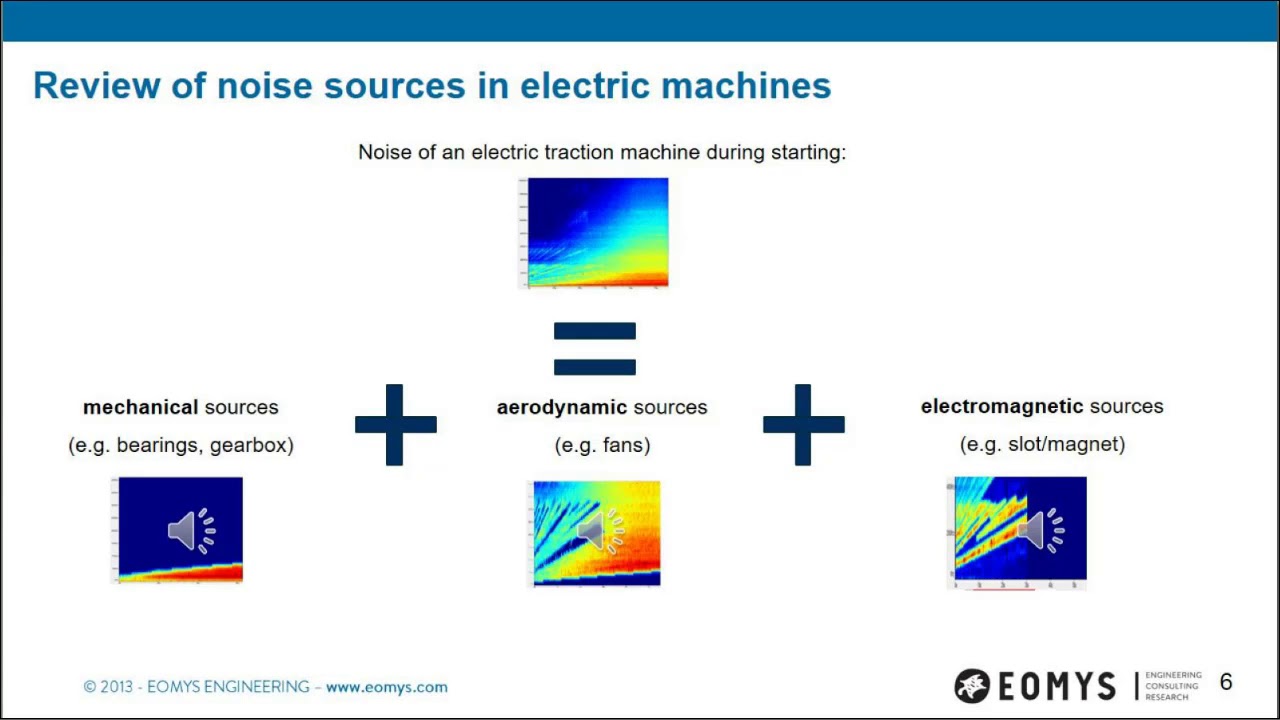

The acoustic noise in induction motors has three main sources. The first one is the ventilating system which is responsible for the noise level of 2 and 4 pole-motors due to the fan speed.