In this review we describe recent technological advances in 3D bioprinting for human tissues. Nowadays scientists are in the midst of moving from printing tiny sheets of tissue to entire 3D organs.

The bioreactor can serve as a simulator to aid in the development of engineering human tissues from.

Bioprinting of human tissues. The key bioink properties for successful bioprinting of human tissue were summarized. After bioprinting the cells are generally devoid of any exposure to fluid mechanical cues such as fluid shear stress tension and compression which are crucial for tissue development and function in health and disease. The bioreactor can serve as a simulator to aid in the development of engineering human tissues from.

Bioreactors have the ability to aid in the development of engineering human tissues from in vitro maturation of 3D cell-laden scaffolds after bioprinting. In this review we describe recent technological advances in 3D bioprinting for human tissues. The processes are beginning from data processing to bioprinting techniques including inkjet laser and extrusion-based bioprinting.

The researchers first designed a new bioink a printable material with cells for 3D-bioprinting human tissue. The bioink was made by combining two materials. Here we describe a method to produce photocrosslinkable tissue-specific dECM bioinks for fabricating patient-specific tissues with high control over complex microarchitecture and mechanical properties using a digital light processing DLP-based scanningless and continuous 3D bioprinter.

We demonstrated that tissue-matched dECM bioinks provided a conducive environment for maintaining high viability and. Recent advances have enabled 3D printing of biocompatible materials cells and supporting components into complex 3D functional living tissues. 3D bioprinting is being applied to regenerative medicine to address the need for tissues and organs suitable for transplantation.

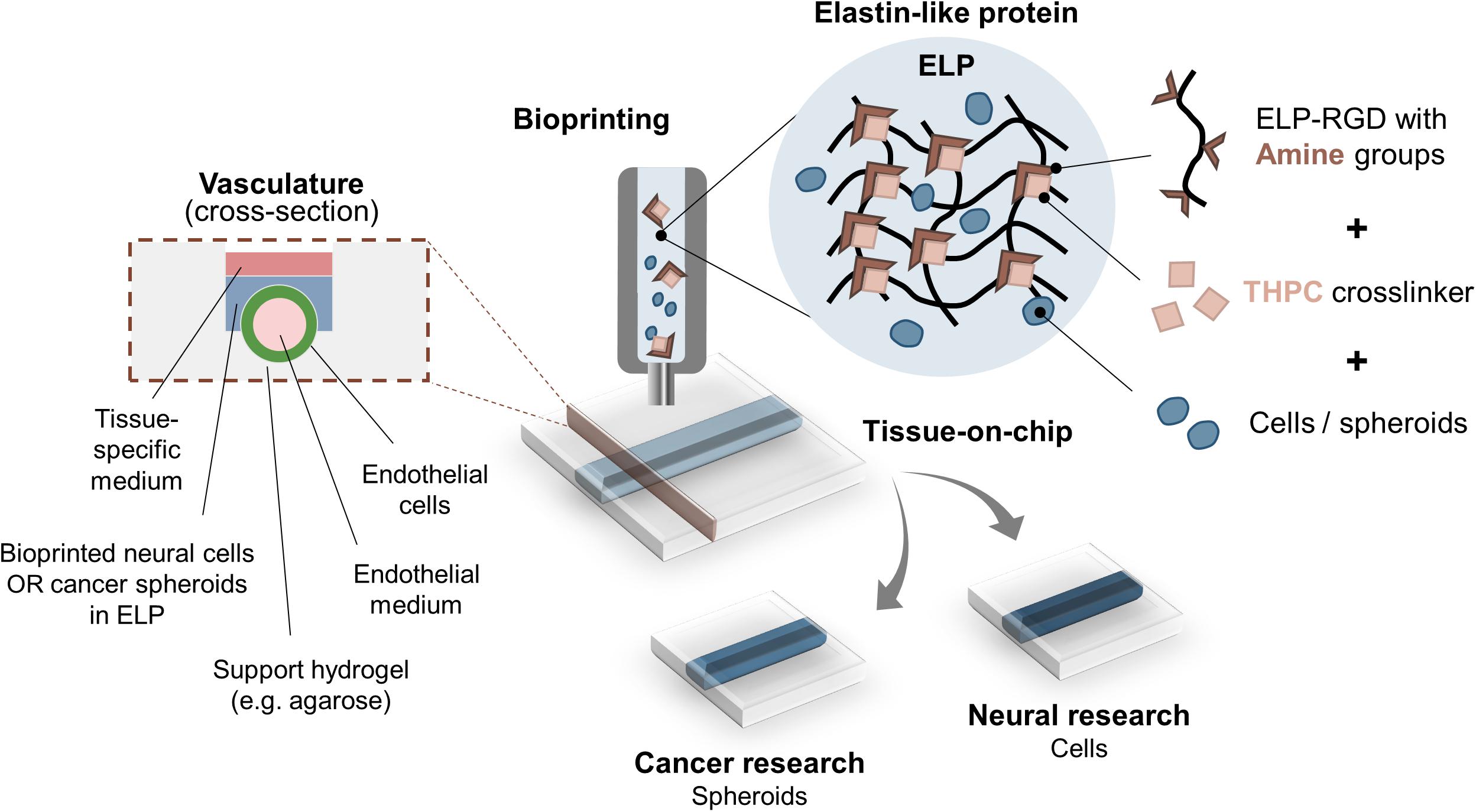

Compared with non-biological printing 3D bioprinting involves additional complexities such as the choice of materials cell types. The lack of in vitro tissue and organ models capable of mimicking human physiology severely hinders the development and clinical translation of therapies and drugs with higher in vivo efficacy. Bioprinting allow us to fill this gap and generate 3D tissue analogues with complex functional and structural organization through the precise spatial positioning of multiple materials and cells.

In this review we report the latest developments in terms of bioprinting. In this case the bioprinted tissues supported high viability and enhanced the tissue-specific gene expression of human adipose-derived stem cells ADSCs human turbinate mesenchymal stem cells hTMSCs and rat myoblast cells when cultured in their respective tissue-matched dECM bioinks compared to collagen I controls which further highlights the advantages of. The Global 3D Bioprinting of Living Human Tissues is expected to grow at a CAGR of 207 from 2021-2027 to reach US 28463 million by 2027.

3D bioprinting of human tissue has been around since the early two-thousands. Nowadays scientists are in the midst of moving from printing tiny sheets of tissue to entire 3D organs. But cultivating live human tissues by hand is a very slow process and scientists searched for ways to make the process more efficient and repeatable.

In 2002 Makoto Nakamura of the University of Toyama Japan discovered that human cells were. A Possible Weapon Against the Pandemic. Printing Human Tissue Bioprinting could be used for testing potential treatments for Covid-19 cancer and other diseases.

We have successfully used FRESH bioprinting method to generate engineered nasoseptal cartilage tissue with molecular biochemical histological and ultrastructural characteristics of native nasoseptal cartilage after a 6week in vitro culture period. These results warrant future mechanical characterization and animal studies in which the bioprinted engineered nasal cartilage will be tested. The field of neural tissue engineering TE is rapidly adopting new technologies that enable scientists to precisely control in vitro culture conditions and to better model nervous system formation function and repair.

3D bioprinting is one of the major TE technologies that utilizes biocompatible hydrogels to create precisely patterned scaffolds designed to enhance cellular responses. Three dimensional 3D bioprinting is the utilization of 3D printinglike techniques to combine cells growth factors andor biomaterials to fabricate biomedical parts often with the aim of imitating natural tissue characteristics. Generally 3D bioprinting can utilize a layer-by-layer method to deposit materials known as bioinks to create tissue-like structures that are later used in.

Explore the science of bioprinting a type of 3D printing that uses bioink a printable material that contains living cells. –There are currently hundreds o. 3D bioprinting of tissue-specific osteoblasts and endothelial cells to model the human jawbone.

3D bioprinting enables free-form fabrication of complex living tissue structures. In the present work production of human jawbone models was realised via projection-based stereolithography. Constructs were bioprinted containing primary jawbone-derived osteoblasts and vasculature-like channel.

Droplet-based bioprinting particularly DOD can be used to precisely pattern the cells in a co-culture or multi-culture platforms but bioprinting human scale tissues is still an onerous task with DOD bioprinting. Extrusion-based bioprinting has the least resolution of all the bioprinting systems but has the highest potential to bioprint human scale tissues and organs. Hence it is important to develop hybrid.